FIELD system Basic Package – An Integrated On-Site Data Platform Built for Smart Factories

NTT DATA and FANUC Joint Development | Empowering Manufacturing to Advance Industry 4.0 and Digital Transformation

Are you facing any of the following issues ?

Site manager

Ops & Maintenance

DX Facilitator

The same abnormal issue keeps occurring repeatedly.

Delivery schedules have to be constantly adjusted.

No real-time visibility into equipment failures once off-site.

Although we’re interested in IIoT, the presence of machines from various manufacturers makes integration difficult.

Solution: NTT DATA & FANUC 【FIELD system Basic Package】

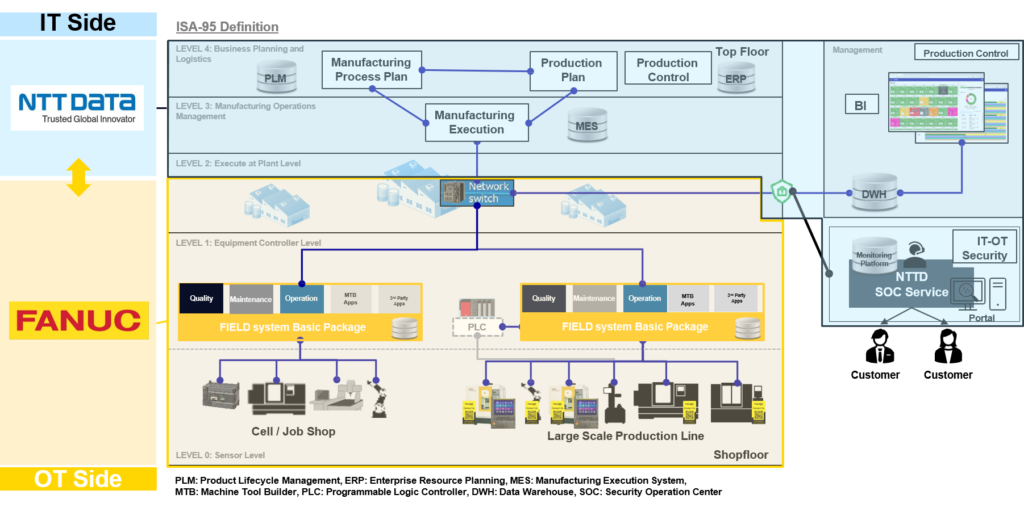

We offer an entry-level MES solution tailored for manufacturing industries, enabling rapid deployment and flexible scalability. Achieve real-time data visualization and on-site monitoring to optimize your production floor management.

On the day of implementation, you can quickly achieve on-site data visualization through “Easy Setup” and “Production Monitoring”, making management more intuitive and decision-making faster.

Its flexible and scalable design allows gradual expansion based on the customer’s usage and the problem-solving stage on the production floor.

From real-time monitoring to seamless integration with external systems, it fully supports your smart factory upgrade journey.

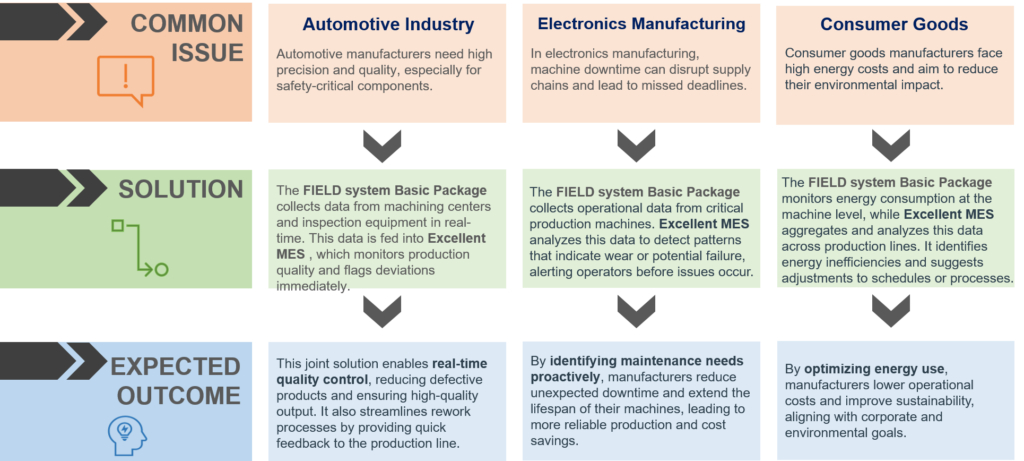

Use Case of Implementation Effectiveness

Company A – Industrial Machinery Parts Processing

Implemented production line performance improvement

approximately 10%.

Company B – Production Equipment Manufacturer

Production line availability increased from 70% to 90%,

achieving an improvement of approximately 20%.

Company C – Precision Parts Processing

Within just one year of implementation, over 80% of equipment achieved an increase in utilization rate of more than 10%.

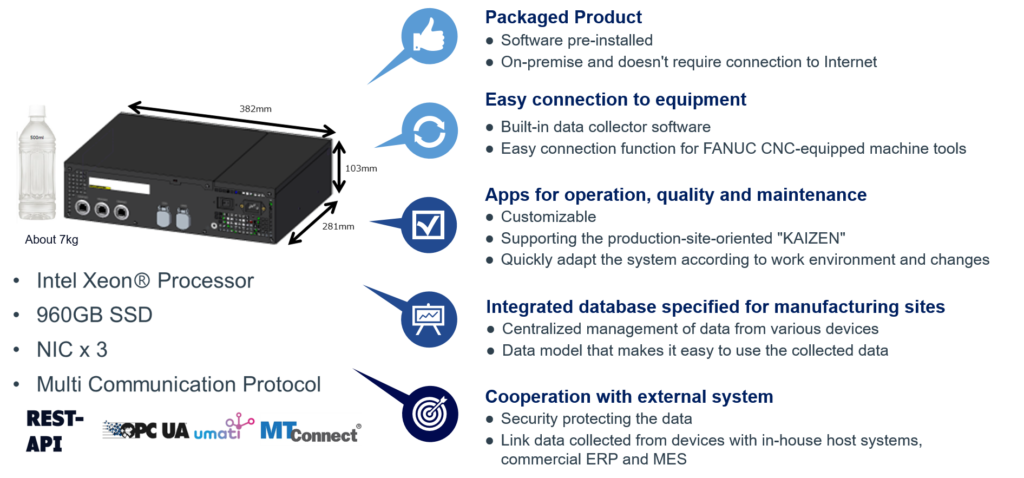

FIELD system Basic Package Features

FIELD system Basic Package Integration

Supports a wide range of protocols commonly used in manufacturing environments, such as:

- FOCAS: FANUC’s protocol connectivity to collect different data from FANUC CNC machines

- OPC UA: A standard protocol for secure and reliable machine data exchange.

- MTConnect: Specifically for CNC machines, providing standardized data output.

- Modbus/TCP: For connecting programmable logic controllers (PLCs) and other industrial automation devices.

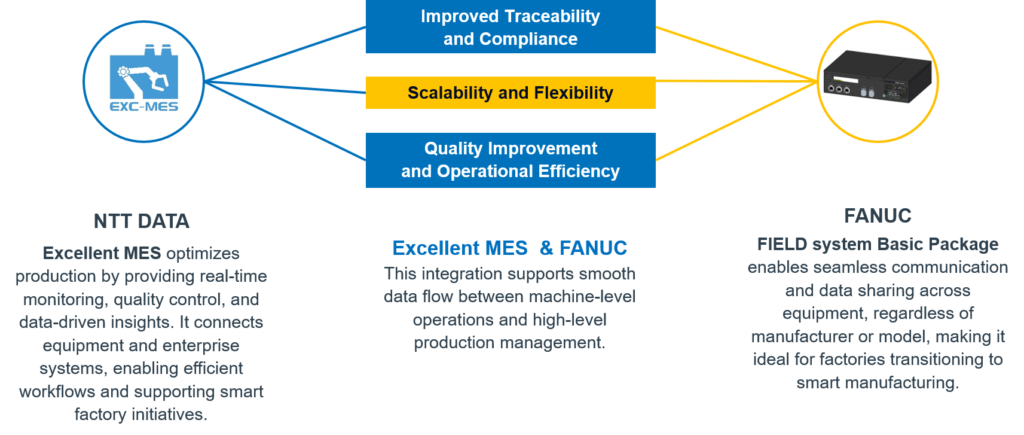

NTT DATA & FANUC Joint Solution Benefits

Applicable Scenarios

Why NTT DATA ?

The strategic partnership with FANUC enables seamless integration of FIELD system Basic Package capabilities with NTT DATA Excellent MES. This ensures optimized performance and streamlined support, leveraging both companies’ strengths.

NTT DATA has extensive experience in manufacturing and digital transformation, offering deep industry insights. Our expertise helps manufacturers effectively integrate FIELD system Basic Package and Excellent MES, tailored to each industry’s unique needs.

With a global presence and local teams, NTT DATA offers responsive support and understands region-specific requirements, providing manufacturers with tailored service wherever they operate.

NTT DATA provides end-to-end digital transformation services, from system integration to data analytics and IIoT solutions, enabling a fully connected, data-driven manufacturing environment.

NTT DATA is committed to innovation, integrating cutting-edge technologies like AI, IoT, and data analytics with FIELD system Basic Package and Excellent MES. This allows manufacturers to stay competitive, improve efficiency, and continuously enhance operations.