Smarter Warehouse Management with Real-Time Automation

Boost efficiency, reduce errors, and optimize logistics with EXC-WMS and AGV integration.

Boost efficiency, reduce errors, and optimize logistics with EXC-WMS and AGV integration.

Enable timely material delivery

Barcode scanning improves the accuracy of inbound and outbound operations. Users can quickly locate materials and ensure timely delivery to reduce production downtime risks.

Go paperless and reduce human errors

EXC-WMS replaces manual paper records in warehouse operations. Data no longer needs to be re-entered into the system manually, enabling real-time material tracking and operation progress monitoring directly within the system.

Enhance transportation efficiency

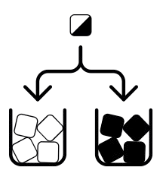

With integrattion of ASRS and AGVs, automated material transportation reduces manual handling and minimizes errors in material placement.

Reduce obsolete inventory

Inventory changes are accurately recorded to ensure alignment with production plans. Effective inventory management improves turnover rates and helps prevent the accumulation of obsolete materials.

Support multiple picking strategies

EXC-WMS can automatically recommend picking materials based on the rules such as First-In, First-Out (FIFO), shortening search time. Combined with visual floor mapping and material search, it allows for quick identification of storage locations for picked items.

Integrate with ERP to ensure data consistency

By consolidating information related to inbound/outbound activities and inventory, EXC-WMS enables real-time communication with ERP, ensuring accurate and synchronized inventory records.

EXC-WMS Features

EXC-WMS Features

SAP ERP Integration

Data is connected through an intermediary database and integrated seamlessly with standard SAP ERP functions.

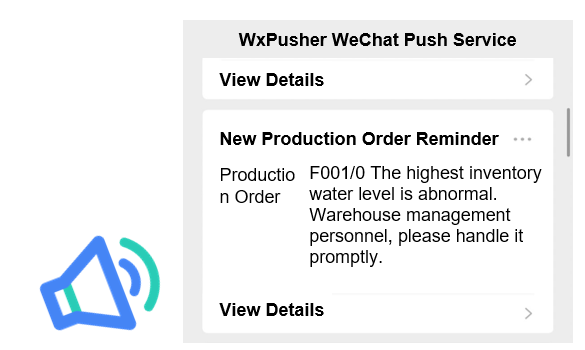

Exception Notifications

Monitor stock levels, expiration dates, and idle inventory duration. If abnormalities are detected, alerts are automatically sent to relevant personnel via messaging platforms.

Modular Flexibility

Containerization and microservices enable quick setup and a robust high-availability (HA) mechanism that can restart services within an average of one minute.

Flexible Integration

EXC-WMS connects with WCS, RCS, and other control systems, enabling automatic material handling via ASRS, AMR, and AGV to enhance operational efficiency.

Cross-Browser Support

Built with responsive web design (RWD), EXC-WMS can be operated on handheld devices equipped with barcode scanners, without requiring any additional app installation.

Visualized Management

Warehouse floor maps use color indicators to display real-time storage conditions, making it easy to identify available locations and monitor inventory status visually.

To ehnace the functuality of EXC-WMS with the adoption of ![]() AGV/AMR integration solutions.

AGV/AMR integration solutions.

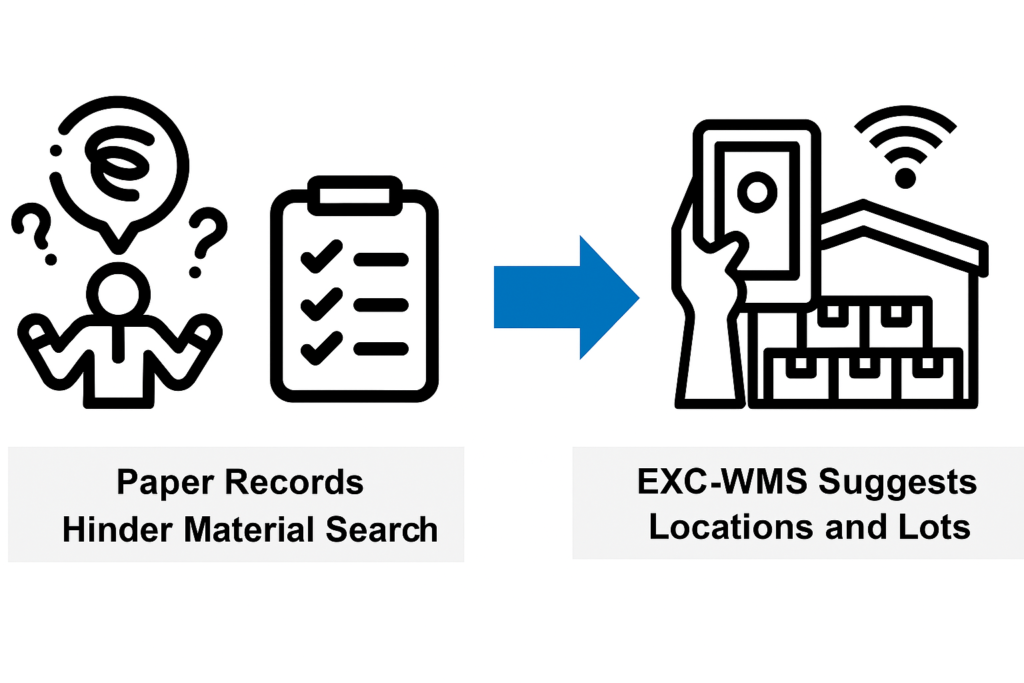

Common Warehouse Management Challenges

1. Paper-Based Records Make Material Traceability Difficult

Inventory data is manually collected and then entered into the ERP by office staff, resulting in long data processing cycles and a lack of real-time inventory visibility.

Real-Time Inventory Tracking and Immediate Exception Handling with EXC-WMS

Real-Time Inventory Tracking and Immediate Exception Handling with EXC-WMS

With barcode scanning and PDA operations, EXC-WMS enables real-time inventory updates. Data processing time is reduced from days to minutes, allowing managers to monitor inventory anytime and respond immediately to anomalies.

2. High Error Rates Due to Manual Operations

Warehouse personnel record data on paper, which is re-entered by office staff into the ERP. This process is time-consuming and labor-intensive, often leading to recording or input errors.

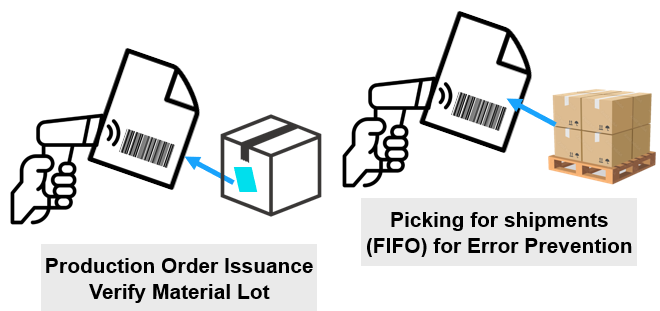

Enhanced Accuracy and Efficiency with Barcode-Driven Picking

Enhanced Accuracy and Efficiency with Barcode-Driven Picking

Using PDAs to scan material lot labels significantly reduces manual input errors. Materials are automatically cross-checked with outbound orders to ensure accurate picking.

3. Inefficient Picking Process

Picking is often based on staff experience and paper documents, which takes more time and increases the risk of incorrect materials being picked.

EXC-WMS Recommends Pick Locations to Improve Efficiency

EXC-WMS Recommends Pick Locations to Improve Efficiency

Based on configured picking strategies, EXC-WMS automatically recommends the storage location and correspinding Lot. Workers simply scan the barcode at the indicated location, enabling fast and accurate picking while reducing time costs.

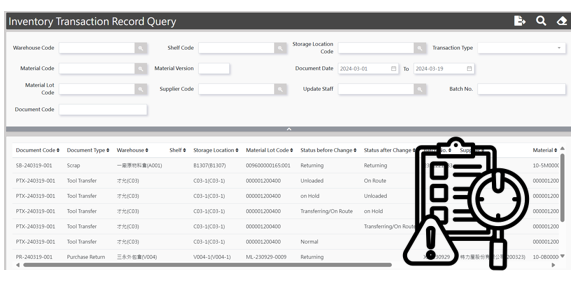

4. Time-Consuming Tool Search in Production

Various tools such as molds and jigs are stored across multiple departments, making them hard to locate when needed. Paper-based records make tracking and analysis difficult.

Reduce Downtime Risk with Storage Visibility for Molds and Jigs

Reduce Downtime Risk with Storage Visibility for Molds and Jigs

When jigs need to be moved, barcode scanning or PDA operations allow accurate tracking within the system. Storage locations can be quickly identified, minimizing the risk of production delays due to missing tools.

5. Lack of Inventory Visibility for Decision-Makers

Plant managers, production planners, procurement, and warehouse supervisors often lack a comprehensive view of material storage across all warehouses, making it difficult to determine production feasibility.

Real-Time Inventory Monitoring and Instant Alerts

Real-Time Inventory Monitoring and Instant Alerts

EXC-WMS continuously monitors inventory safety levels, expiration dates, and idle stock duration. When abnormalities are detected, alerts are automatically sent via Line, email, or WeChat to the relevant personnel.

Learn our ideas about “Bolg- Warehouse management system“.

EXC-WMS Modules

EXC-WMS Modules

Master Data

- Master data maintenance for carriers (e.g., pallets, boxes), personnel, suppliers, materials, and other related data.

- Function settings include multi-language support, permission mgmt., and multi-factory mgmt.

Warehouse Management

- Real-time recording of material inbound and outbound transactions with inventory anomaly alerts.

- Warehouse floor map visualization displays storage utilization.

- Inventory counting functionality to ensure stock accuracy and consistency.

Data Exchange

- Integrate with SAP ERP, and MES systems, exchanging master data via intermediary tables.

- Support standardized interfaces for AGV, AMR, and ASRS integration.

- Compatible with WCS, MCS, and RCS systems.

Alarm Management

- Configure alerts for equipment, quality, & production performance.

- Set alert recipients and delivery methods: Line, WhatsApp, WeChat, push notifications, etc.

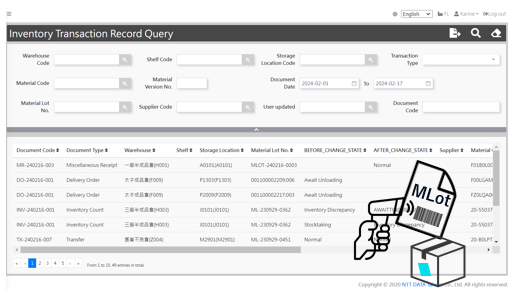

Report & Dashboard

- Provide a real-time warehouse dashboard.

- Offer warehouse information queries, including inventory lot lookup, inventory transaction records, and shipping details.

Sorting Operations

- Master data maintenance for sorting in/outbound operations.

- Physical layout of buffer racks/seeding walls.

- Control strategies for handling equipment, including barcode verification and max bin capacity.