Industry Overview

When enterprises evaluate or initiate digital transformation and smart manufacturing projects, they face numerous technologies and solution options. To define a clear roadmap—including short-, mid-, and long-term strategies, phases, timelines, and execution—expert consultation is essential to align with the company’s operational direction.

Among diverse technologies such as IT (Information Technology), CT (Communication Technology), and OT (Operation Technology), the choice of products and solutions varies depending on each enterprise’s digital ecosystem, production model, process capability, management culture, and operational needs.

Therefore, when planning and executing digital transformation, it is critical to balance investment vs. benefit, evaluate system coverage, data necessity, and ensure ease of use. Under these complex challenges, selecting an experienced consulting partner is key to successfully achieving a holistic and effective transformation strategy.

NTT DATA’s consulting team supports clients by adopting a guided approach during the blueprint phase. Based on the enterprise’s industry type, consultants conduct structured workshops to collect and analyze business requirements. From experience, many companies struggle to consolidate detailed requirements within a short time.

To address this, NTT DATA first provides solution awareness and training, helping key users understand system functions and potential operational improvements. Guided discussions then help each department refine and confirm functional and process requirements, reducing ambiguity during planning and identifying opportunities for process, operational, and management optimization.

In addition, during the blueprint stage, NTT DATA consultants leverage industry-proven management templates to accelerate system scenario confirmation and improve applicability. These templates, derived from common operational needs such as production scheduling, process data collection, material and quality management, recipe control, and dashboard visualization, offer flexible front-end interfaces including mobile app templates. This approach minimizes customization, shortens implementation time, and ensures relevance across industries.

NTT DATA’s solutions adopt a microservice and container-based architecture, combined with industry-specific templates tailored to sectors such as metalworking, textiles, chemicals, assembly, injection molding, automotive manufacturing, and more. These templates encapsulate typical production and management characteristics, enabling faster deployment and higher adaptability during system implementation.

Key Considerations for Digital Transformation Planning

Enterprises planning digital transformation and smart manufacturing are advised to implement in phases, based on their current level of digital maturity. Each stage can be adjusted flexibly depending on business needs, priorities, and budget. The recommended implementation roadmap is as follows:

(1) Foundational Digital Platform

Building a digital factory is the foundation for digital transformation and smart manufacturing.

The goal is to migrate lean management practices onto a digital platform that delivers real-time, data-driven, and transparent operational efficiency.

Typical foundational applications include:

- Virtual factory setup

- Electronic and real-time quality management

- Integrated equipment connectivity

- Management reporting platform

- Real-time operation dashboard

- ERP integration

(2) Optimization after Digital Transformation

After the foundational platform is established, employees begin adapting to data-driven operations and decision-making.

During this stage, optimization needs become clearer and more actionable.

The goal is to enhance baseline applications and deepen specialized functionalities for each management unit.

Typical applications include:

- Smart scheduling (APS )

- Smart warehouse management (WMS, ASRS)

- Preventive maintenance management

- Unmanned transport applications (AGV/AMR, AMHS, MCS )

- Data platform and big data applications (Big Data / Data Platform)

(3) Data Value-Added Applications

With a stable foundation and optimized processes, enterprises can transition to data-driven management.

Collected manufacturing data—from machines, materials, and operations—can be analyzed to generate insights and predictive intelligence.

Whereas past decision-making often relied on experience or senior expertise, digital transformation enables knowledge to be codified and continuously improved through data analytics.

- Digital Twin implementations

- AI-driven manufacturing insights

- Human–machine collaboration

- Fully unmanned factory operations

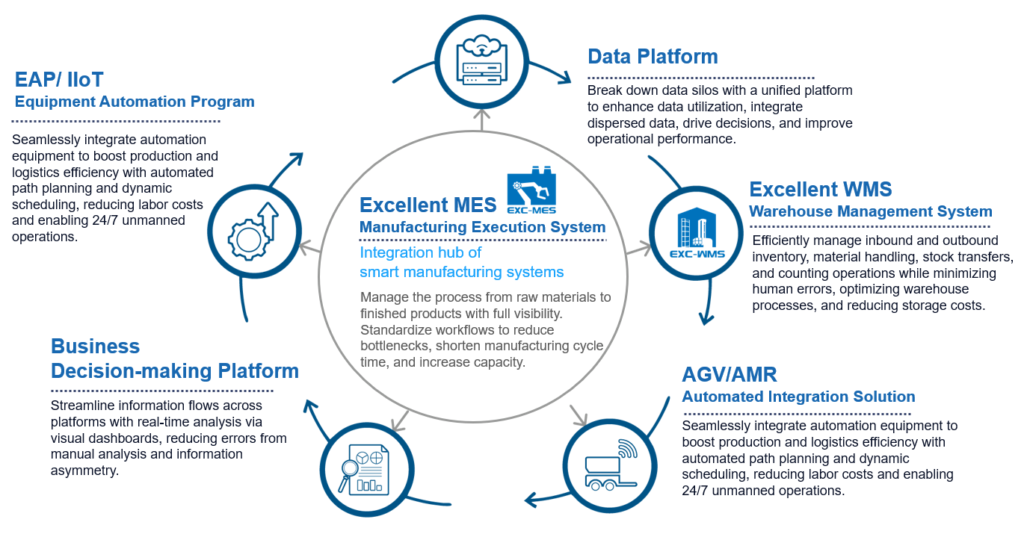

NTT DATA Solutions

NTT DATA offers comprehensive services for digital transformation and smart manufacturing, with extensive experience across multiple industries.

Our service scope includes:

- MES implementation

- AGV/AMR automation planning

- EAP/IIoT integration

- System integration (IT/OT connectivity)

- Dashboard and control room development

- Data platform and AI-driven analytics

- Project management with Jira

Benefits Analysis

The primary goal of digital transformation and smart manufacturing is to enhance competitiveness through digital tools and platforms.

With the guidance of professional consultants, enterprises can develop tailored digital strategies that fit their operational characteristics and management culture.

By aligning digital platforms with business goals, companies can realize tangible benefits in productivity, quality, and decision-making efficiency.

NTT DATA serves as your dedicated partner in this journey—turning digital transformation into measurable, sustainable business value.

Ready to start your digital transformation journey?

Let NTT DATA help you build a roadmap for smart manufacturing — from planning to implementation.![]() Contact Us

Contact Us